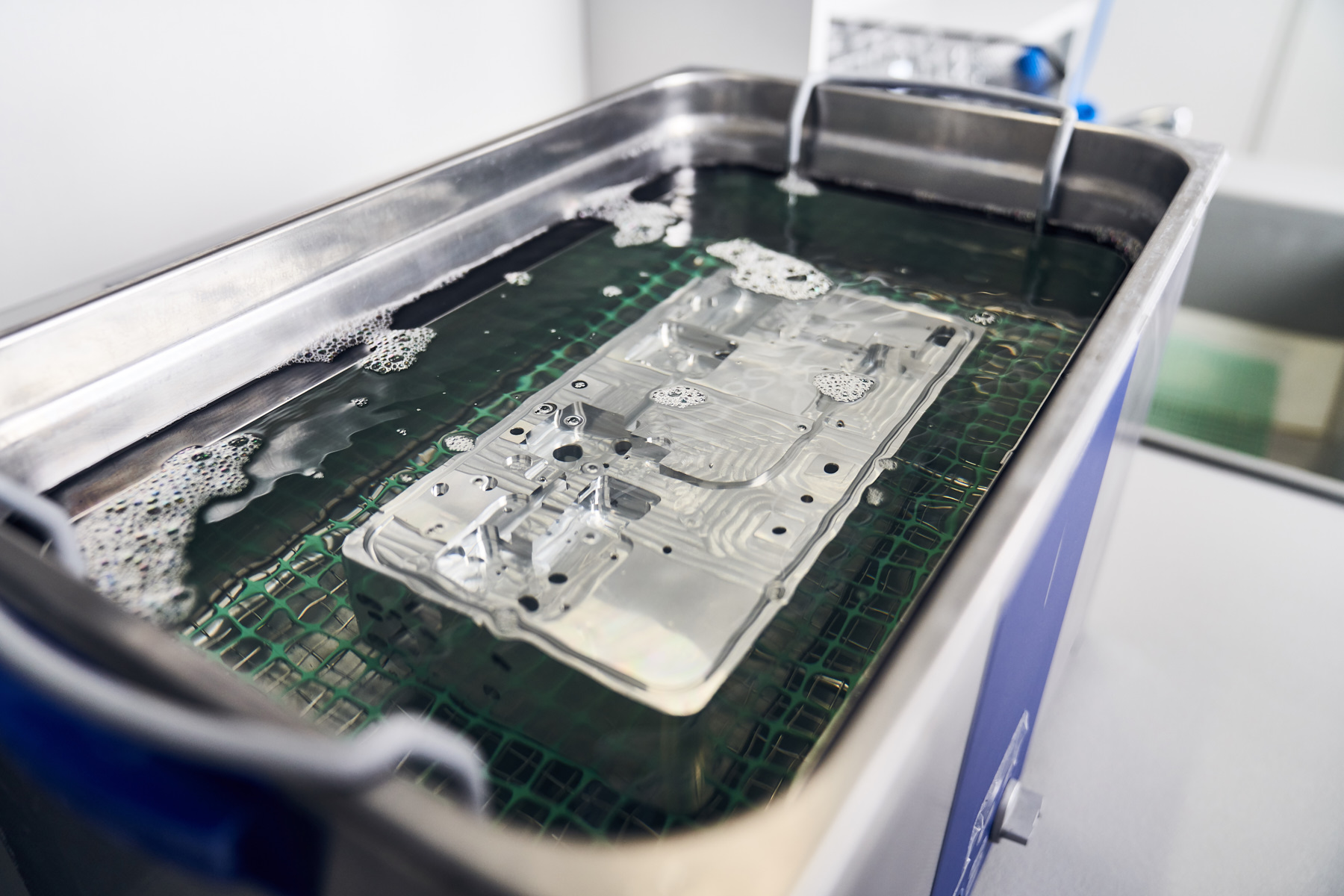

Precision Cleaning

After the parts are made, there are still some coolant-emulsion residues or chips left on the surface. If the parts do not undergo a precision cleaning procedure and are used as lasers component the emulsion residues start to evaporate and pollute the laser optics. This is the main reason why precision cleaning should be performed after any mechanical processing of laser components.

This process is organized into three stages. Firstly, we rinse the surface emulsion residue with a water jet so that it does not dry up. During the second stage, the parts are cleaned on the cleaning line with the help of an ultrasound to drain all the dirt from the holes and then washed with deionized water (distilled water). The third step is washing and blow-drying the holes and drying the components in the ovens. After the third stage is complete, the surface is inspected under the UV lamp.

Other services